Steel Yourself for Change: Fully Optimized Master Production Schedules

DELMIA Quintiq

SEPTEMBER 16, 2021

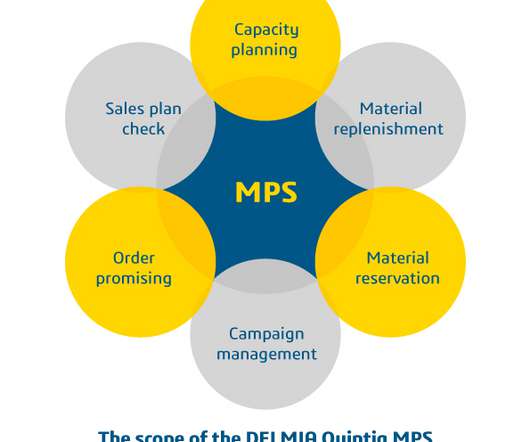

Meeting these objectives, on top of addressing existing industry challenges, requires steel manufacturing companies to become more efficient and flexible in their operations—and this means optimizing their master production schedules. As your steel manufacturing operations transform, so too will the complexity of your planning needs.

Let's personalize your content