How Can You Improve Value in Your Supply Chain?

Supply Chain Shaman

JANUARY 7, 2025

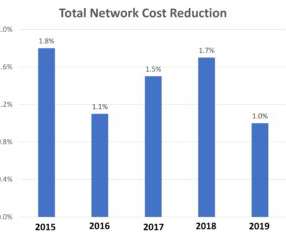

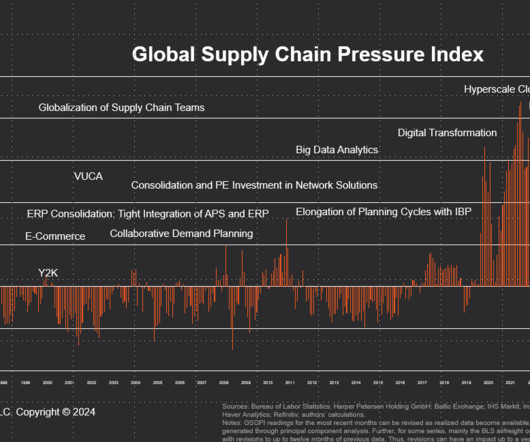

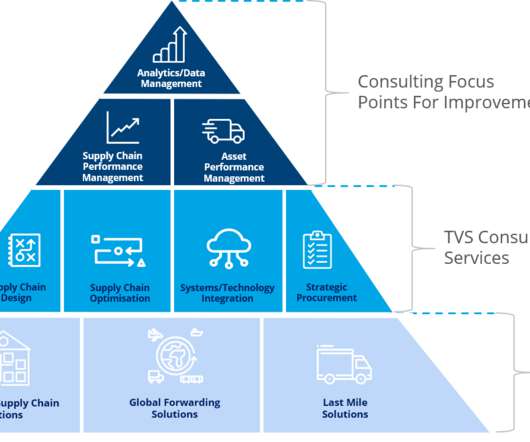

Sorting through this to make a decision on a new planning solution at this time is tough. For example, if I improve the cost structure in transportation, procurement, manufacturing and sales independently, what decision support framework decides the right trade-offs? My advice? You are right. How Do You Drive Value? Your next step?

Let's personalize your content