Inventory Everywhere, But Not the Right Product to Ship

Supply Chain Shaman

MARCH 21, 2023

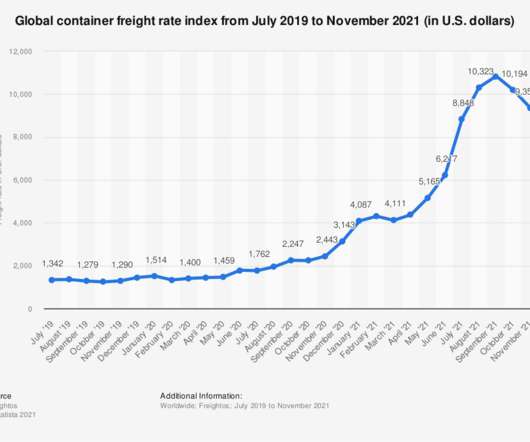

Note that in Figure 1, retail home improvements days of inventory increased 68 days, contract manufacturing days increased 48 days, retail apparel by 28 days, and containers and packaging manufacturing companies by 14 days. Despite investments in planning, today, industries hold 28 more days of inventory than in 2004.

Let's personalize your content