Importance of Digitalisation to Improve Supply Chains: Helping Businesses Navigate Through Supply Chain Disruptions

The Logistics & Supply Chain Management Society

AUGUST 19, 2022

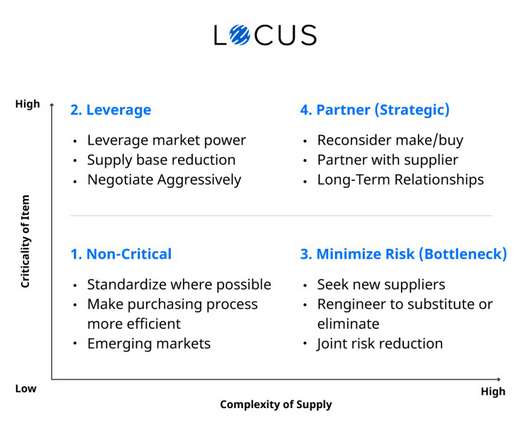

Importance of Digitalisation to Improve Supply Chains: Helping Businesses Navigate Through Supply Chain Disruptions. is adopted in more and more industries and companies, the supply chain industry is starting to implement these disruptive technologies to adapt to the ongoing challenges and obstacles.

Let's personalize your content