How Can You Improve Value in Your Supply Chain?

Supply Chain Shaman

JANUARY 7, 2025

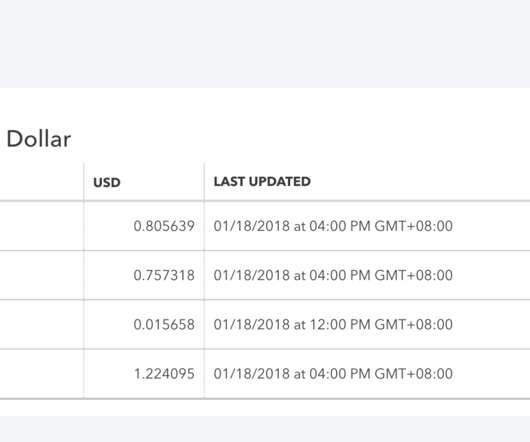

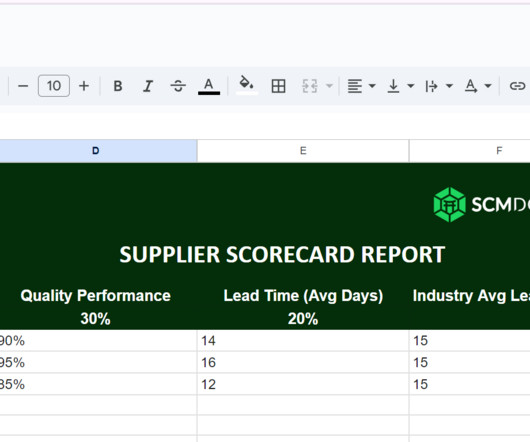

For example, if I improve the cost structure in transportation, procurement, manufacturing and sales independently, what decision support framework decides the right trade-offs? The Y chart service harmonizes the data across different public markets, currencies, M&A, and restatements. You are right. This work was expensive.

Let's personalize your content