Outside-in Process Q&A

Supply Chain Shaman

FEBRUARY 26, 2024

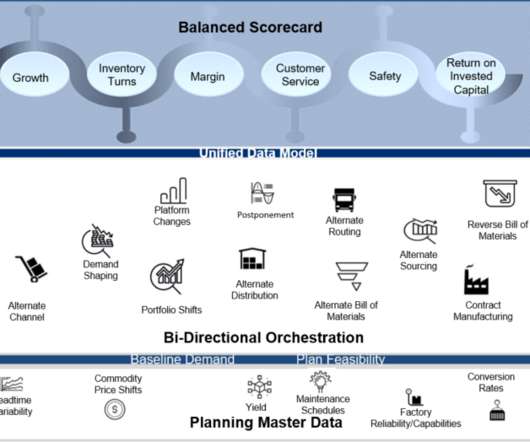

Based on the work with Georgia Tech, we are getting clear on which metrics matter by industry. As companies adopt a balanced scorecard, the functional metrics shift to a focus on reliability. For example, in manufacturing, the shift in focus is away from OEE to focus on first pass yield and schedule adherence.)

Let's personalize your content