Ahead of the Curve: How Digitalization Helped Air Cargo Amidst Red Sea Shipping Diversions

Freightos

APRIL 2, 2024

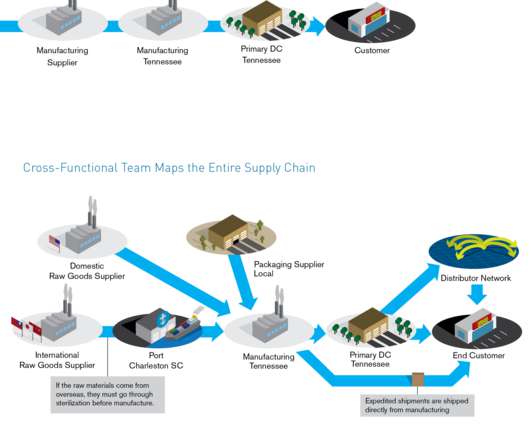

Schedules were quickly disrupted and capacity shifted to China – Europe and North America lanes to accommodate the longer voyages. These changes made ocean capacity (and empty containers) scarce, sending container rates out of India spiking. That reached air cargo quickly.

Let's personalize your content