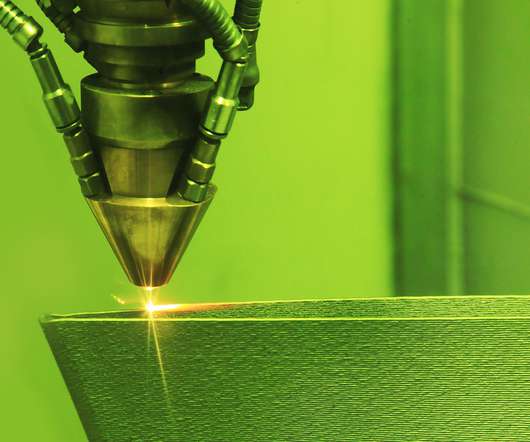

Leveraging Technology in the Warehouse to Enable Safe Social Distancing

SphereWMS

AUGUST 13, 2020

Active warehouses are hubs of human activity. Pulling and loading inventory is an ongoing process in the highly dynamic distribution centers of today. To maximize floor space, which amounts to revenue potential for the facility, operators have reduced aisle space to a minimum in order to optimize storage space. But in a new era of social distancing requirements, these spaces where the most human interaction occurs must be re-evaluated.

Let's personalize your content