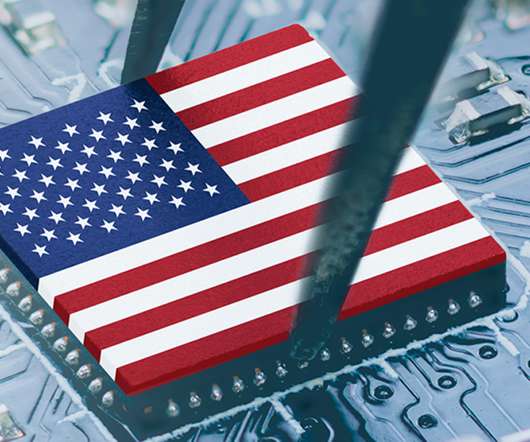

Global Supply Chains in Flux as U.S. Tariffs on Canada, Mexico, and China Take Effect

Logistics Viewpoints

MARCH 4, 2025

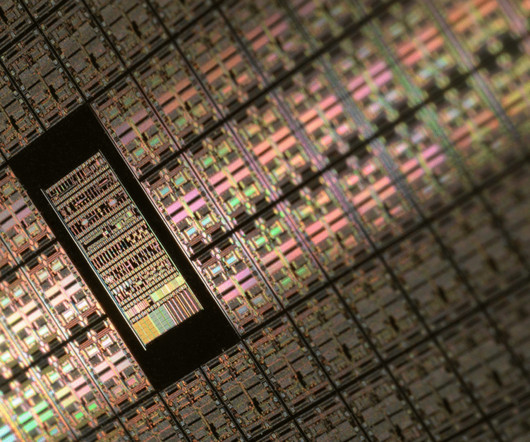

The 25% tariffs on Canadian and Mexican imports and 20% tariffs on Chinese goods are expected to increase production costs, disrupt logistics networks, and force companies to rethink supply chains. This includes: Increasing domestic supply chain investments, reducing dependence on cross-border components.

Let's personalize your content