Energy Transition in Supply Chain

Logistics Viewpoints

FEBRUARY 7, 2024

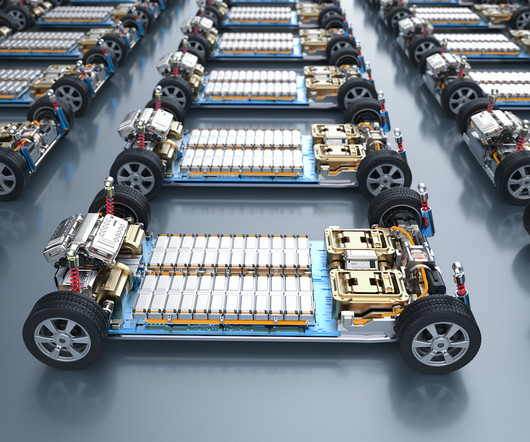

Supply chain sustainability has become a very hot topic, but for a lot of people, there is uncertainty around its meaning. Now, more than ever, companies and countries are looking at their overall carbon footprint and trying to establish a path to be more environmentally friendly. A few ways companies can begin to offset their carbon footprint is to take a deeper look at product packaging, energy efficiency, alternative fuels, route optimization, and returns and recycling programs.

Let's personalize your content