Global Supply Chain Disruptions: Covid-19’s Ripple Effect Continues + 5 Changes Needed for 2022

ToolsGroup

DECEMBER 20, 2021

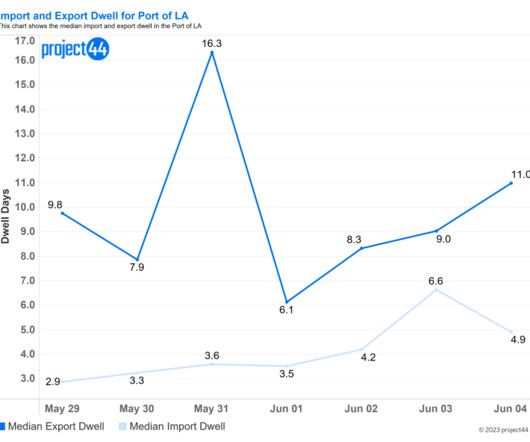

The problems we are experiencing now started in March 2020 when COVID hit and suppliers in Asia shut down. . When capacity was cut, so too was the empty supply of containers back to Asia. Image source: Bloomberg. Labor shortages , impeding the ability to get cargo unloaded, loaded, or moved. Let me bring that to life. .

Let's personalize your content